Air Conditioning Cleanroom Project

| Project Scope (from structure, HVAC, electric to auto-control) | Structure: Wall Panel, Ceiling Panel, Windows, Doors, Fittings, Flooring |

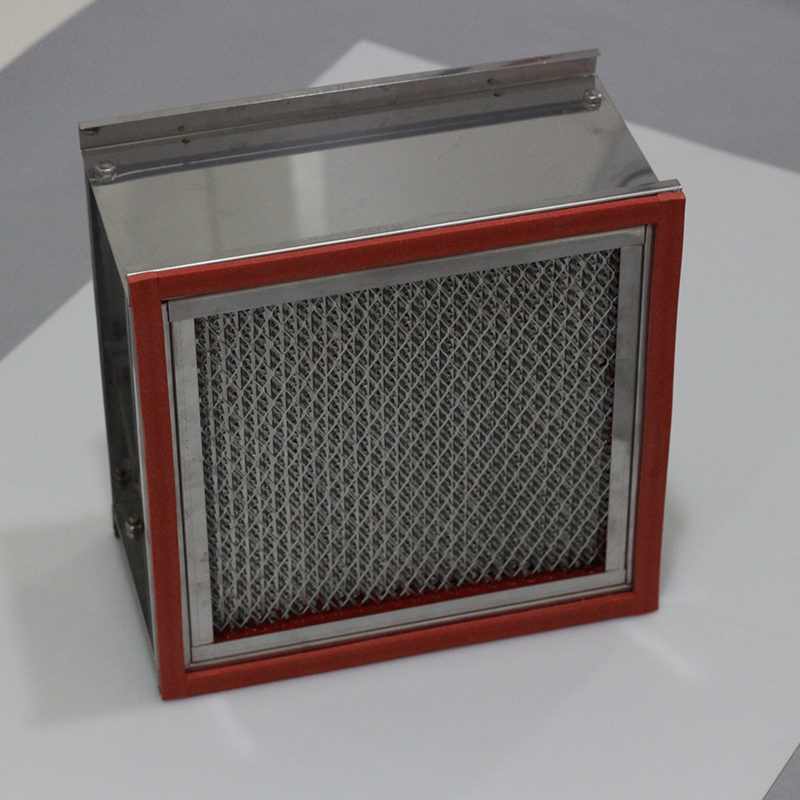

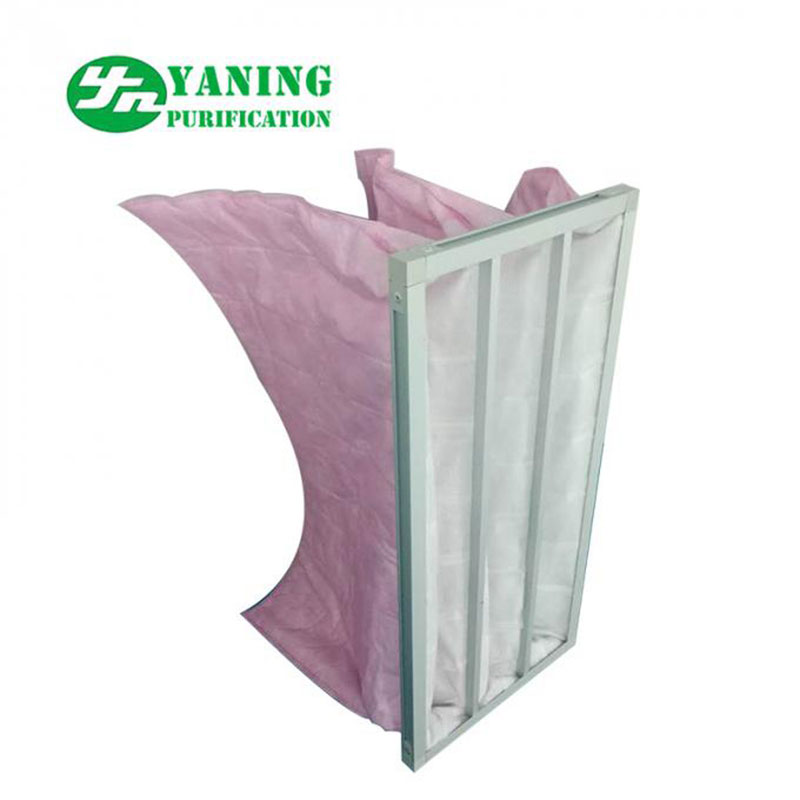

| HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. | |

| Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc. | |

| Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel | |

| Process Piping System: Gas, Water Pipeline | |

| Equipment | Air shower, Pass box, Cargo shower, Sampling booth, Weighing booth, Temperature and humidity chamber, Isolator, VHP space sterilizer, etc. |

| Temperature | 21-27℃ (or as per required) |

| Humidity | 30-60℃ (or as per required) |

| Application | Pharmaceuticals, hospital, electronics, food, cosmetics, etc. |

| Qualification Documents | DQ, IQ, OQ, PQ |

| Full Service | FAT and SAT Service, Professional Consultation, Training, User-friendly English Sofaware, 24 hours technical support. |

Cleanroom service scope: including manufacturing, construction, installation, and after-sale service.

Cleanroom construction standard (GMP):

- Class 100-100000

- ISO 5-8

- Class A-D

Advantage: 10 years' experience in a cleanroom area.

Lead-time:

- Material manufacturing: about 15-30 days.

- Construction: 1-3 months according to site conditions and area.

Write your message here and send it to us